我們始終相信:成功之道來自於奉獻和給予,明諦集團 新園工業追求讓生活微笑開心與人類生活更美好的一切事物。

明諦集團 新園工業 是一家創立於台灣的高性能材料公司。我們研發並製造先進的高分子材料、和特用化學品。國際企業尋求明諦集團一起將產品提升到新的水準,同時盡量減少對環境的影響。

自成立以來,明諦新園工業 透過各方面的貢獻以追求技術精進,這意味著公司竭盡所能,不斷地提升員工、客戶、終端用戶和世界的生活品質。

PRODUCTS

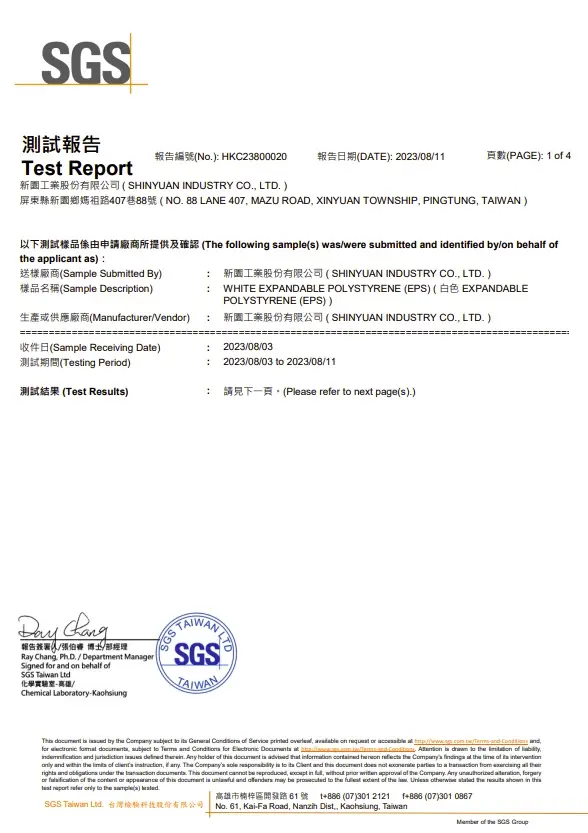

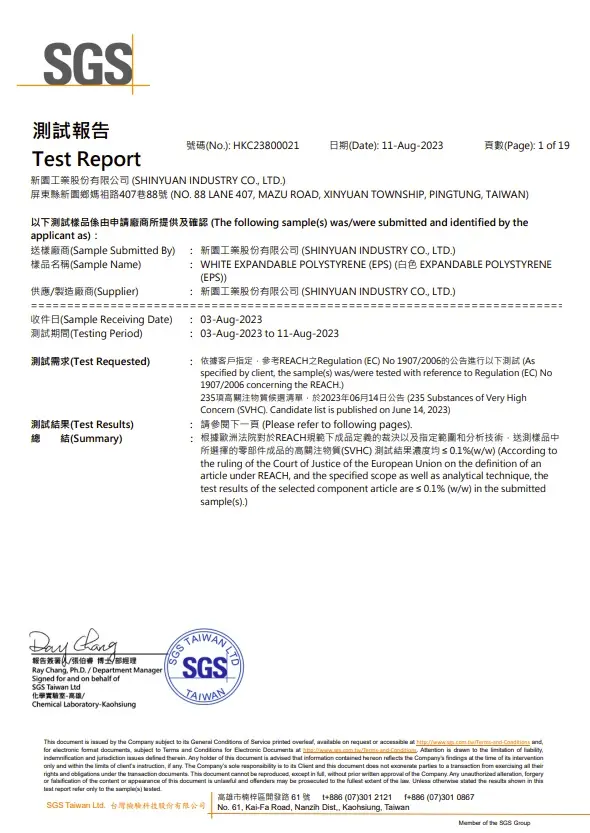

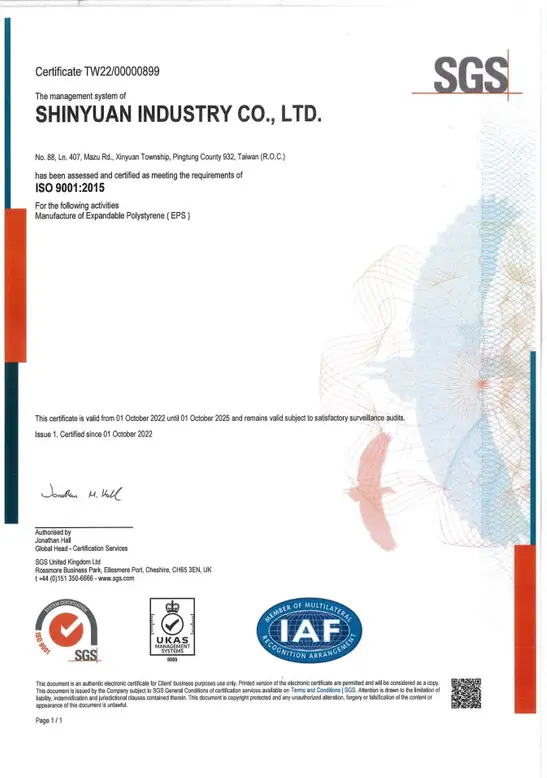

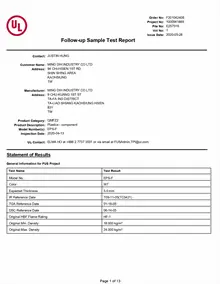

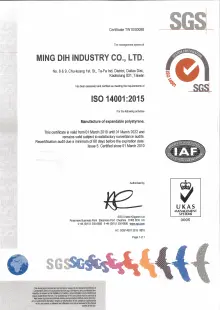

CERTIFICATE

& REPORT

& REPORT

APPLICATION

FAQ

發泡結塊

- 發泡溫度太高—調整發泡溫度,控制EPS流量一致

- 蒸氣含水太多—檢查冷凝水排放管線是否暢通

- 局部過熱—檢查蒸氣分佈,避免加熱不均

潮濕

- 蒸氣潮濕—將蒸氣管路保溫,設疏水管線

- 發泡機保溫不良—加強桶體保溫

泡粒收縮

- 蒸氣壓力太高或溫度高—降低蒸氣壓力,調低發泡溫度

- 泡粒進料太少或滯留太久—調整進料速度或泡粒出口擋板

- 發泡倍率過高—使用二次發泡以達到所需倍率

發泡倍率不均

- 進料速度不均—疏通送料系統或調整進料速度

- 新舊原料混合使用—儘量使用同批號原料

- 蒸氣壓力不穩定—檢查蒸氣管線,增加減壓閥穩定蒸氣壓力

發泡倍率低

- 蒸氣溫度低—提高蒸氣量及提高壓力

- 在發泡機內停留時間太短—提高出料口高度

- 泡粒過期倍率不足—良好的貯存管理

- 出料太快—降低出料速度

POOR FUSION

- STEAM SUPPLY—CHECK STEAM SUPPLY SYSTEM, ADJUDGE HEATING PERIOD

- MOULD PROBLEM— STEAM SPIRACLES DESIGN, CLEAN STEAM SPIRACLES AND SCALE, IMPORVE MOULD SEALING

- LONG AGING TIME—SHORTEN AGING TIME

- OVER-EXPANDED BEADS—CONTROL DENSITY

- *HIGH HUMIDITY OF FOAMED BEADS—PROLONG AGING TIME, DRYING THE BEADS

- *COATING PROBLEM—WELL CONTROL COATING

MOULD RELEASING PROBLEM

- OVER HEATING—REDUCE HEATING TIME OR/AND HEATING TEMPERATURE

- INSUFFICIENT COOLING—CHECK COOLING SYSTEM, PROLONG COOLING TIME

- MOULD PROBLEM—SMOOTHEN THE MOULD, CLEAN OR RENEW SPIRACLES, EJECTION ARMS

- COMPRESS AIR PROBLEM—CHECK COMPRESS AIR SYSTEM

SHRINKAGE

- OVER HEATING—SHORTEN OR/AND REDUCE HEATING TIME

- OVER COOLING—REDUCE WATER COOLING

- INSUFFICIENT FILLING—CHECK FILLING SYSTEM, PROLONG FILLING TIME

- MOULD LUCKING—ADJUDGE PRESSURE

- INSUFFICIENT AGING—PROLONG AGING TIME

- OVER EXPANDED BEADS—CONTROL DENISTY

SWELLING OR DEFORM

- INSUFFICIENT AGING—PROLONG AGING

- OVER EXPANDED BEADS—CONTROL DENSITY

- UNEVEN HEATING—CHECK HEATING SYSTEM

- UNEVEN OR INSUFFICIENT COOLING—CHECK COOLING SYSTEM, IMPROVE COOLING

- LOW TEMPERATURE AMBIENT—USE DRYING ROOM

DIFFERENT WEIGHT

- UNEVEN PRE-EXPANSION—CONTROL PRE-EXPANSION PROCESS

- MIXED LOT MATERIAL—CONFIRM MATERIAL

- WIDE BEADS SIZE DISTRIBUTION—CHECK MATERIAL